Selecting the Correct Metal for Your End-Use: Aluminum, Stainless or Carbon Steel?

When planning a fabrication or manufacturing project, choosing the right metal is critical to performance, cost, and longevity. Each material: aluminum, stainless steel, and carbon steel has its own strengths, weaknesses, and best-fit applications.

Understanding the differences between these metals helps engineers, fabricators, and purchasing managers make smarter material decisions and prevent costly mistakes.

Aluminum: Lightweight, Corrosion-Resistant, and Versatile

Overview:

Aluminum is one of the most widely used materials across industries for its lightweight strength and corrosion resistance. As a non-ferrous metal, aluminum doesn’t rust, making it an excellent choice for outdoor or marine environments.

Key Properties:

About one-third the weight of steel, reducing shipping and handling costs

Naturally corrosion-resistant due to its protective oxide layer

Highly formable and machinable, ideal for custom metal fabrication

Excellent thermal and electrical conductivity, useful in power, HVAC, and energy applications

Common Applications:

Transportation: automotive, aerospace, and marine components

Construction: architectural panels, curtain walls, and roofing systems

Industrial equipment and enclosures

Electrical and HVAC systems

Cost and Performance:

Although aluminum may cost more upfront than carbon steel, its lightweight efficiency and low maintenance can lower long-term project costs. It’s ideal when weight reduction and corrosion resistance are more valuable than raw strength.

Stainless Steel: Strength and Corrosion Resistance Combined

Overview:

Stainless steel is a premium metal known for its strength, longevity, and visual appeal. Its chromium content (typically 10.5% or higher) provides a strong layer of corrosion resistance, making it a top choice for demanding or sanitary environments.

Key Properties:

High tensile strength for load-bearing applications

Superior corrosion and heat resistance, even in harsh conditions

Available in multiple finishes (2B, No. 4, BA) for aesthetic and functional use

Withstands frequent cleaning and high temperatures

Common Applications:

Food processing and pharmaceutical equipment

Architectural and decorative panels and railings

Chemical processing and marine environments

Medical instruments and components

Cost and Performance:

Stainless steel has a higher initial cost but delivers exceptional lifespan and minimal maintenance. For industries where cleanliness, corrosion resistance, or appearance are priorities, stainless steel offers strong long-term value.

Carbon Steel: Durable, Affordable, and Widely Available

Overview:

Carbon steel remains the most popular choice for general manufacturing and construction. It provides excellent strength, high durability, and is easy to machine, weld, and form.

Key Properties:

Outstanding strength and hardness, especially in higher carbon grades

Cost-effective for large-volume or structural projects

Easily fabricated and welded for a variety of end uses

Can be painted, coated, or galvanized for additional corrosion protection

Common Applications:

Construction beams and supports

Machinery parts and industrial equipment

Automotive frames and structural components

Cut-to-length and slitted sheet for manufacturing

Cost and Performance:

Carbon steel is typically the most affordable option. However, it is more susceptible to corrosion without proper surface treatments. It is best suited for indoor, dry, or coated applications where cost efficiency is the priority.

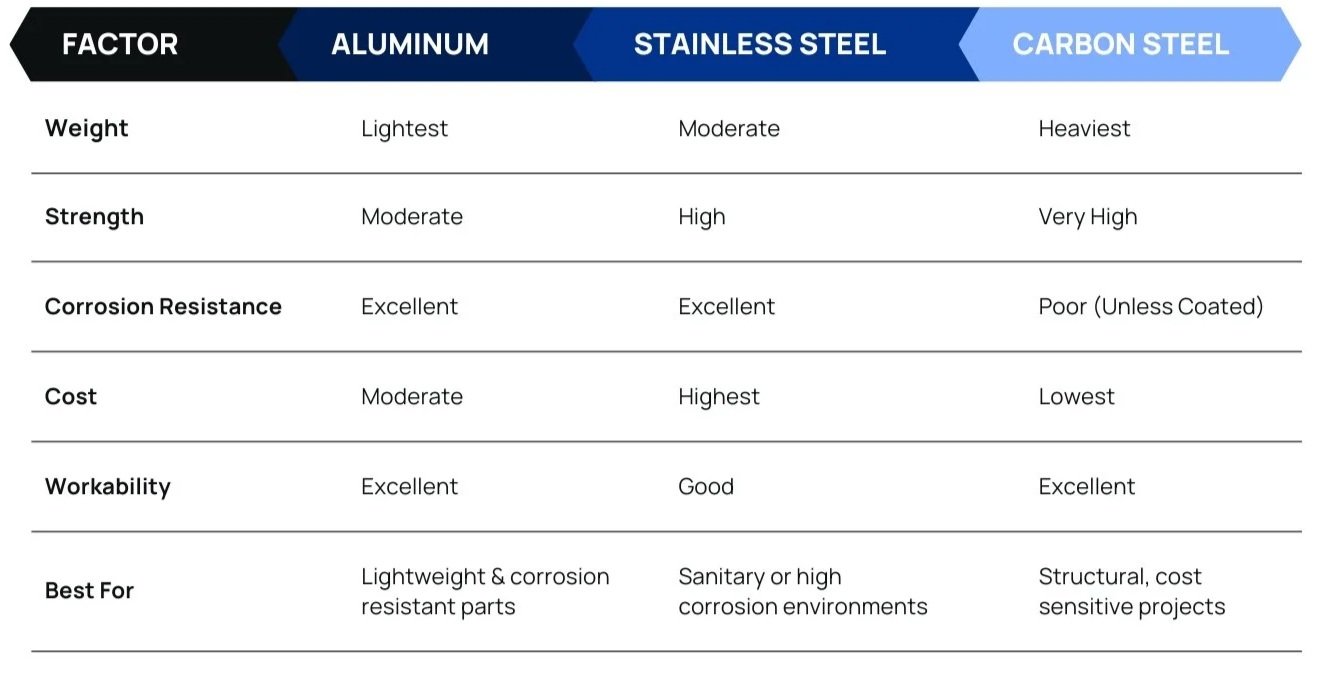

See How Each Metal Measures Up

Stronger Projects Start With the Right Metal

The right metal depends on your application, environment, and performance goals.

Choose aluminum for lightweight corrosion resistance.

Choose stainless steel for durability, cleanliness, and aesthetics.

Choose carbon steel for reliable strength at a lower cost.

At Basic Metals, Inc. we stock and process a full range of aluminum, stainless, and carbon steel coils and sheets, ready to be cut-to-length, slit, or sheared to your exact specifications. Our team can help you evaluate which material best fits your project, balancing performance and cost efficiency.

Ready to discuss your next project?

Contact Basic Metals, Inc. to connect with our experts and get personalized recommendations for your metal selection needs!